SMA33 has 4 sets of curves, 10 in each group, and a group of 40 maximum curves, each with a maximum time of 99 hours and 59 minutes. The program can have 9999 cycles. When power is cut off on site, the program can continue to run from the power off, and the running parameters can also be modified. Accuracy 0.2 and liquid crystal window display.

Advanced regional PID(zone) technology, the implementation of PID parameters can be automatically converted with the bottom temperature zone-medium temperature zone-high temperature zone three regions.

The two sets of independent event relays presented can set up 16 kinds of events, 9 kinds of alarms: upper and lower limit absolute values, upper and lower limit deviation values, inner/outer error alarm methods, and can further set the alarm return difference and processing countermeasures.

In the high quality heat treatment process, it is necessary to ensure the precise processing time into the insulation area(platform). The allowable deviation when the temperature reaches the platform can be set, and the program will be automatically delayed until the deviation due to the system lag or overregulation is overcome. After the temperature reaches the platform, the program in the insulation area begins to record time.

Energy saving servo start, the first section of the program jump to the actual furnace temperature point to start execution, rather than waiting for the program to start the set value, effectively save energy and time.

Isolate digital communication interface(optional), RS 485(port address 1 ~ 255), various communication protocols.

Simulated Variation Output(Select): optional measurement value setting, deviation value, and adjustment output variable for field data recording.

Advanced regional PID(zone) technology, the implementation of PID parameters can be automatically converted with the bottom temperature zone-medium temperature zone-high temperature zone three regions.

The two sets of independent event relays presented can set up 16 kinds of events, 9 kinds of alarms: upper and lower limit absolute values, upper and lower limit deviation values, inner/outer error alarm methods, and can further set the alarm return difference and processing countermeasures.

In the high quality heat treatment process, it is necessary to ensure the precise processing time into the insulation area(platform). The allowable deviation when the temperature reaches the platform can be set, and the program will be automatically delayed until the deviation due to the system lag or overregulation is overcome. After the temperature reaches the platform, the program in the insulation area begins to record time.

Energy saving servo start, the first section of the program jump to the actual furnace temperature point to start execution, rather than waiting for the program to start the set value, effectively save energy and time.

Isolate digital communication interface(optional), RS 485(port address 1 ~ 255), various communication protocols.

Simulated Variation Output(Select): optional measurement value setting, deviation value, and adjustment output variable for field data recording.

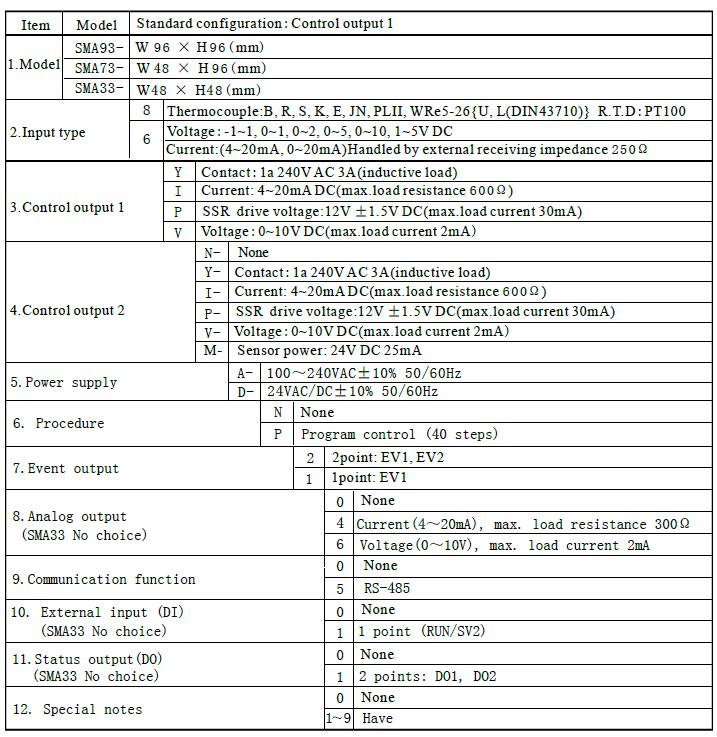

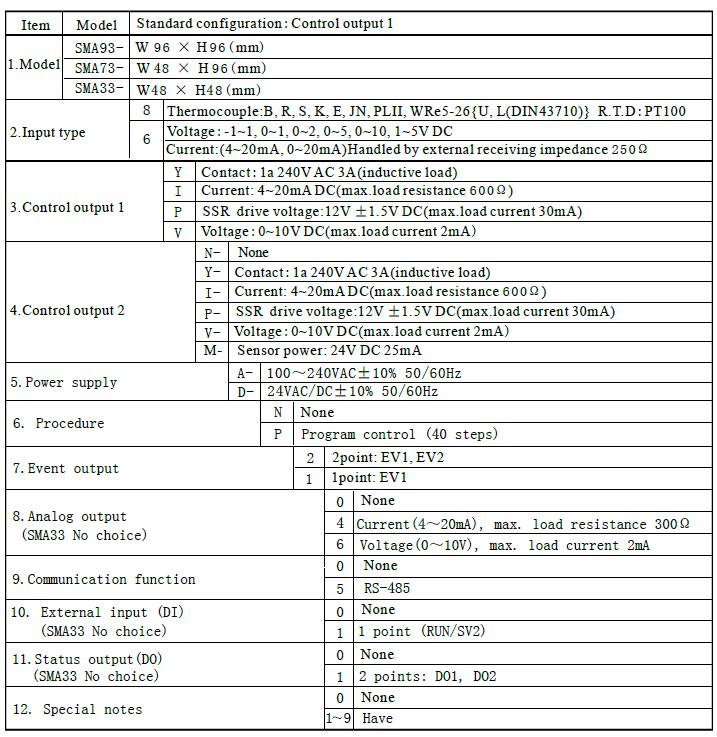

Model Selection table